#Dairy plant and equipment manufacturer

Explore tagged Tumblr posts

Text

Dairy plant and equipment manufacturer in India

We “Saffron Machinery” have gained success in the Dairy plant and equipment manufacturer market by Manufacturing and Exporting a remarkable gamut of Dairy Machinery, Milk And Dairy Plant, Milk Storage Tank, Juice Processing Plant, Industrial Chiller, Ice-Cream Processing Machinery And Plant, CIP System, Bulk Milk Cooler, Mango Processing Plant, Fruit & Vegetable Processing Plant, Cold Room, etc. We are a well-known and reliable company at Ahmedabad (Gujarat, India). Our offered products are manufactured in compliance with the pre-defined industry norms and tested to ensure their flawlessness. Our Mission is To discover, deploy, develop and direct the available resources to enable them to demonstrate their optimum capacities to attain the highest possible level of productivity, profitability and customer satisfaction. Providing self employment in Rural India thereby improving their standard of living. We also Offering Industrial Erection Service to Our Client.

Incorporated in 2016 as Saffron Machinery with State-of-the-art Manufacturing unit of Dairy Equvipment, Food Processing Plants, Industrial Chillers And Amonia Chilling Plants,cold Rooms.

Highly skilled, dedicated, experienced work force.

0 notes

Text

What to Look for in Dairy Plant Machinery Manufacturers

When selecting the dairy plant machinery manufacturers there are several factors that one should consider, one of them being that the manufacturers should have rich experience in the industry. Long experience comes from different manufacturers that fully understand the potentiality and specific demand of the dairy sector, and they assure their supporting machineries to be as effective and durable as possible.

Expertise of a certain level creates unique designs, allowing to engineer and manufacture sophisticated equipment that meets the best industry standards, including energy saving and automation. Skilled manufacturers have the capability of constructing valued equipment like pasteurizers, homogenizers and separators which are necessary in the processing of dairy products.

Dairy plant machinery manufacturers with many years of experience, services can confidently be relied upon to increase efficiency while not compromising quality.

High-Quality and Durable Equipment

There is no doubt that processing of dairy requires the sourcing of the best and most efficient equipment that could last long. The leading manufacturers of dairy plant machinery focus on using durable materials such as stainless steel which is well recognized for strength, rust resistance and ease in cleaning, which must be cardinal in dairy plants.

Typically, intricate techniques like welding and computerised numerically controlled machining are used to create not only the precision but the durability of machinery for constant use. It also increases the durability of the equipment so that it has low incidences of breaks and thus low repair bills.

Quality is a major consideration at Aviva Equipment. Through advanced technology and acquiring high-quality materials, Aviva guarantees machinery that meets industry requirements and customers’ expectations. They are one of the few dairy plant machinery manufacturers that have not faltered in terms of their focus on the reliability and efficiency of their products.

Customization and Flexibility

This means that every business entity in the dairy industry must have special requirements for its production processes. Be it small scale operations or large industrial operations, there is a strong need of customization to carry on efficient operations and quality products. This is where machinery manufacturers of dairy plants come in handy by providing customization and flexibility.

The ability to design machinery to fit the particular needs means that companies can target issues like production rate, space, and appearance. From a pasteurizer designed for an artisanal cheese producer to a homogenizer for large-scale milk processing, customization matches equipment to purpose.

Similarly, flexibility in machinery layouts means that the dairy businesses can easily expand or contract production lines, or even introduce new products or lines into its operation. These needs are important and respected by proficient dairy plant machinery manufacturers who offer equipment that evolves with the business to guarantee not only its sustainability but also its happiness.

Compliance with Industry Standards

To machinery manufacturers of the dairy plant, conformity to standards is not a choice. Dairy principally requires high standards of food safety and hygiene in order to produce safe quality dairy foods. Manufacturers must work with non porous products and designs that can avoid contamination of the fluids therefore using stainless steel products that specialize in foods and have smooth finishes.

Basic certifications showing the company’s commitment to international standards include ISO 9001 for quality assurance and FDA for food products. These certificates can be considered as reliable signals that the equipment provided corresponds to the necessary safety, hygiene, and functional standards.

Compliance not only serves to reduce the risks of harm to the end consumer but also builds the image of a brand. The regulation of dairy equipment standards ensures that dairy businesses can proudly present products to the market. Selecting compliant manufacturers of dairy plant machinery is one way of guaranteeing long term sustainability and consumers’ confidence.

Choosing the Right Manufacturer

Choosing of right dairy plant machinery manufacturers is therefore crucial to optimal operation, quality production and componential standards. Some of the aspects to consider are manufacturer experience, longevity and quality of the equipment, opportunity for customization, safety compliance, and dedicated customer service after the sale.

Even though cost cannot be ignored, it is essential to focus on quality and long-term screw reliability, as well as quality customer support.

For better and more unique products, please see Aviva Equipment’s dairy plant machinery products that are designed to fit any business. Step up your dairy production with reliable solutions and innovative tools.

#dairy processing equipment#aviva equipment#dairy processing equipment manufacturers in india#Dairy Plant Machinery Manufacturers

0 notes

Text

#dairy plant machinery manufacturers#dairy equipment suppliers#dairy processing plant manufacturer#SM Engineering

1 note

·

View note

Text

Fast and High-Quality Dairy Product Production with Mini Dairy Plant Machinery and Equipment

Efficient and high-quality production is essential in the ever-changing dairy industry. To keep up with the rising demand for high-quality, freshly-dairy products, small and medium-sized dairy companies require dependable, high-performance solutions. Milk Processing Plant and Machines for micro dairy plants come into play here, allowing for rapid, scalable, and high-quality milk production.

#Milk Processing Plant and Machines#Milk Processing Plant and Machines Manufacturers#Milk Processing Plant and Machines Suppliers#Milk Machines#Milk Processing Machines#Milk#Dairy Equipment#Dairy Machines#Dairy Machine Manufacturers

0 notes

Text

Saffron Machinery is a leading dairy plant and equipment manufacturer in India, specializing in milk processing plant solutions. Our extensive range includes dairy machinery, milk storage tanks, juice processing plants, and industrial chillers, all designed to meet the highest industry standards. Based in Ahmedabad, Gujarat, we are committed to delivering reliable and efficient products that enhance productivity and profitability. Our mission focuses on optimizing resources while promoting self-employment in rural India, thereby improving living standards. Additionally, we provide industrial erection services, ensuring comprehensive support for our clients in the dairy and food processing sectors.

1 note

·

View note

Text

Mini Dairy Plant Cost in India

Looking for a reliable Mini Dairy Plant Manufacturer in India? Look no further than Divyom Processing Machinery & Equipments. While we are well-known for our Mini Dairy Plant, we also specialize in state-of-the-art milk processing solutions. Contact us today for more details!

#Mini dairy plant manufacturer#Mini dairy plant manufacturer in India#Mini dairy plant supplier inn Inida#Mini dairy plant manufacturer in Ghaziabad#Mini dairy plant manufacturer in Delhi NCR#Mini dairy plant supplier in Delhi#Mini dairy plant supplier in Ghaziabad#divyom process machinery & equipments

1 note

·

View note

Text

#dairy equipment#dairy equipment manufacturers#dairy processing equipment#dairy processing equipment manufacturers#dairy plant manufacturers#dairy plant#dairy plant machinery

0 notes

Text

How to start and run a milk processing plant?

The milk plant is a place, premises where milk is collect, process, store, pasteurize, packaged and prepared for supply. The milk processing plant machine must have license for it. In this license, a mini milk processing plant may prefer to process to dairy and milk products. There are many dairy business plants all over India. The whole process starts in dairy farms which have cattle such as cows, buffaloes and goats for milking purposes.

Capacity of Milk Processing Plants

Milk Plants are small, medium and big. These use different types of milk processing equipments according maximum milk capacity per day. There are number of dairy products like ghee, cream, butter, toned milk, double toned milk and skimmed milk that are also manufactured in milk plant. Milk is initially dumped in big milk tank from the milk tankers after that it chilled in a chilling unit. This chilled milk is pasteurized in the milk pasteurizer and cream is divided from the cream separator which gets skimmed milk. Milk is generally depends on the necessity of toned milk, skimmed milk, double toned milk or full cream milk.

Process of dairy Processing Plants

The proper milk production is very vital in the dairy farm. Dairy cows are milked 2 times in a day in all dairy farms. The big farms use good equipments for the processing procedure. After that, it is transferred to big refrigerated milk tanks. These milk tanks are collected by big trucks that transport the product to the milk processing plants. It is important to check the taste and temperature of product before transporting the product to milk processing plants that is suitable for use or not. If the truck is transported to the processing plants then the milk processing plant is pumped into special tanks. After that, it is taken for separation and clarification procedure.

Advertisements

In the milk processing plants, the product separates from bacteria that it is perfect for use. This procedure is well-known as clarification. It is turn in huge vats for some time and the initial spin separates every types of bacteria and fragments from the product. It turns again to separate heavy and light milk. After that, the process involves heat the product to destroy the remaining bacteria present in it. The product is heated and passed all the way through steel pipes in procedure of pasteurization. The next step is homogenization that eliminates fat from the product. The product is heated to decrease the fat particles that present in it. Without the procedure of homogenization, fat particles would float over the milk. Therefore, these processes are very helpful for milk processing business and also for plants.

if you have any query please feel free to ask me

Pranam Ji Engineering Works Khasra No 346, Jalapur, Raghunathpur Muradnagar, Ghaziabad, Uttar Pradesh-201206 +91 7017598033, 9315662914 8920968610, 8126573005

#milk dairy#dairy equipment#plant milk#manufacture#suplier#dairy cows#milk products#milk processing plant

0 notes

Text

Milton Orr looked across the rolling hills in northeast Tennessee. “I remember when we had over 1,000 dairy farms in this county. Now we have less than 40,” Orr, an agriculture adviser for Greene County, Tennessee, told me with a tinge of sadness.

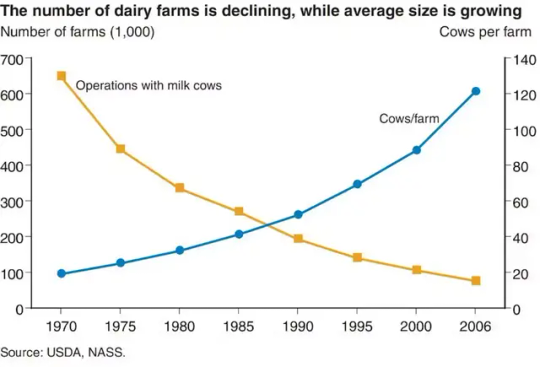

That was six years ago. Today, only 14 dairy farms remain in Greene County, and there are only 125 dairy farms in all of Tennessee. Across the country, the dairy industry is seeing the same trend: In 1970, more than 648,000 US dairy farms milked cattle. By 2022, only 24,470 dairy farms were in operation.

While the number of dairy farms has fallen, the average herd size—the number of cows per farm—has been rising. Today, more than 60 percent of all milk production occurs on farms with more than 2,500 cows.

This massive consolidation in dairy farming has an impact on rural communities. It also makes it more difficult for consumers to know where their food comes from and how it’s produced.

As a dairy specialist at the University of Tennessee, I’m constantly asked: Why are dairies going out of business? Well, like our friends’ Facebook relationship status, it’s complicated.

The Problem with Pricing

The biggest complication is how dairy farmers are paid for the products they produce.

In 1937, the Federal Milk Marketing Orders, or FMMO, were established under the Agricultural Marketing Agreement Act. The purpose of these orders was to set a monthly, uniform minimum price for milk based on its end use and to ensure that farmers were paid accurately and in a timely manner.

Farmers were paid based on how the milk they harvested was used, and that’s still how it works today.

Does it become bottled milk? That’s Class 1 price. Yogurt? Class 2 price. Cheddar cheese? Class 3 price. Butter or powdered dry milk? Class 4. Traditionally, Class 1 receives the highest price.

There are 11 FMMOs that divide up the country. The Florida, Southeast, and Appalachian FMMOs focus heavily on Class 1, or bottled, milk. The other FMMOs, such as Upper Midwest and Pacific Northwest, have more manufactured products such as cheese and butter.

For the past several decades, farmers have generally received the minimum price. Improvements in milk quality, milk production, transportation, refrigeration, and processing all led to greater quantities of milk, greater shelf life, and greater access to products across the US. Growing supply reduced competition among processing plants and reduced overall prices.

Along with these improvements in production came increased costs of production, such as cattle feed, farm labor, veterinary care, fuel, and equipment costs.

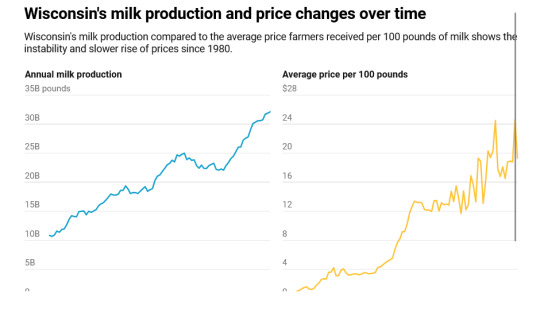

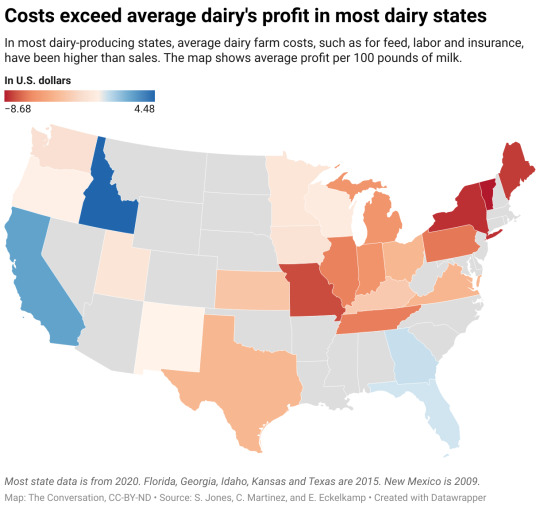

Researchers at the University of Tennessee in 2022 compared the price received for milk across regions against the primary costs of production: feed and labor. The results show why farms are struggling.

From 2005 to 2020, milk sales income per 100 pounds of milk produced ranged from $11.54 to $29.80, with an average price of $18.57. For that same period, the total costs to produce 100 pounds of milk ranged from $11.27 to $43.88, with an average cost of $25.80.

On average, that meant a single cow that produced 24,000 pounds of milk brought in about $4,457. Yet, it cost $6,192 to produce that milk, meaning a loss for the dairy farmer.

More efficient farms are able to reduce their costs of production by improving cow health, reproductive performance, and feed-to-milk conversion ratios. Larger farms or groups of farmers—cooperatives such as Dairy Farmers of America—may also be able to take advantage of forward contracting on grain and future milk prices. Investments in precision technologies such as robotic milking systems, rotary parlors, and wearable health and reproductive technologies can help reduce labor costs across farms.

Regardless of size, surviving in the dairy industry takes passion, dedication, and careful business management.

Some regions have had greater losses than others, which largely ties back to how farmers are paid, meaning the classes of milk, and the rising costs of production in their area. There are some insurance and hedging programs that can help farmers offset high costs of production or unexpected drops in price. If farmers take advantage of them, data shows they can functions as a safety net, but they don’t fix the underlying problem of costs exceeding income.

Passing the Torch to Future Farmers

Why do some dairy farmers still persist, despite low milk prices and high costs of production?

For many farmers, the answer is because it is a family business and a part of their heritage. Ninety-seven percent of US dairy farms are family owned and operated.

Some have grown large to survive. For many others, transitioning to the next generation is a major hurdle.

The average age of all farmers in the 2022 Census of Agriculture was 58.1. Only 9 percent were considered “young farmers,” age 34 or younger. These trends are also reflected in the dairy world. Yet, only 53 percent of all producers said they were actively engaged in estate or succession planning, meaning they had at least identified a successor.

How to Help Family Dairy Farms Thrive

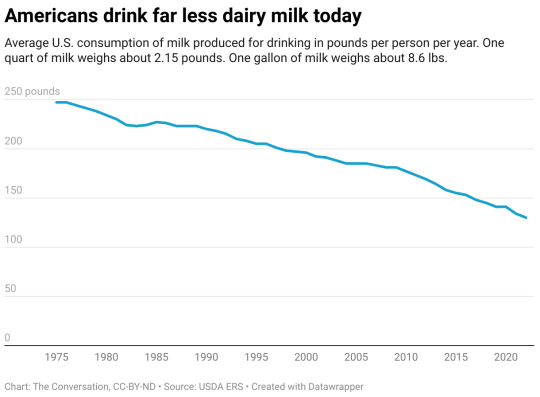

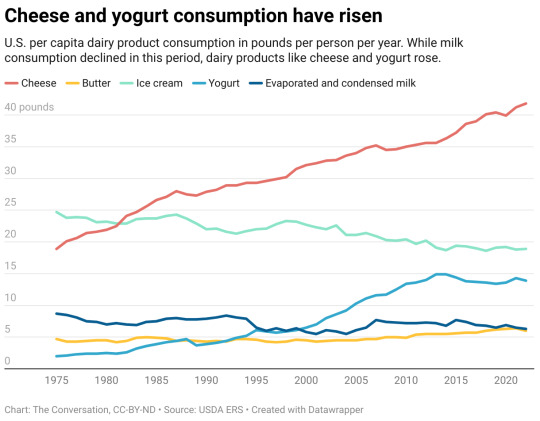

In theory, buying more dairy would drive up the market value of those products and influence the price producers receive for their milk. Society has actually done that. Dairy consumption has never been higher. But the way people consume dairy has changed.

Americans eat a lot, and I mean a lot, of cheese. We also consume a good amount of ice cream, yogurt, and butter, but not as much milk as we used to.

Does this mean the US should change the way milk is priced? Maybe.

The FMMO is currently undergoing reform, which may help stem the tide of dairy farmers exiting. The reform focuses on being more reflective of modern cows’ ability to produce greater fat and protein amounts; updating the cost support processors receive for cheese, butter, nonfat dry milk, and dried whey; and updating the way Class 1 is valued, among other changes. In theory, these changes would put milk pricing in line with the cost of production across the country.

The US Department of Agriculture is also providing support for four Dairy Business Innovation Initiatives to help dairy farmers find ways to keep their operations going for future generations through grants, research support, and technical assistance.

Another way to boost local dairies is to buy directly from a farmer. Value-added or farmstead dairy operations that make and sell milk and products such as cheese straight to customers have been growing. These operations come with financial risks for the farmer, however. Being responsible for milking, processing, and marketing your milk takes the already big job of milk production and adds two more jobs on top of it. And customers have to be financially able to pay a higher price for the product and be willing to travel to get it.

33 notes

·

View notes

Note

Where does red army get their supplies and food? Wym

Most of it is cultivated by the army themselves. They plant and grow their own produce in especially built and equipped greenhouses. Of course, livestock is another matter altogether; since they are so hard to mantain the Red Army synthesizes all meat and dairy products instead.

Other supplies like weapons are manufactured by the scientists in the engineering department, the tools to make such weapons scrapped from junkyards, and medicine is given to them by pharmaceutical companies that they made deals with.

12 notes

·

View notes

Text

Stainless Steel 304 Tube

No doubt that stainless steel 304 tubes stand in the list of most variable groups of useful products from metal industries as due to the massive usage of that material by large numbers of most industries on its account because the corrosion resistance happens to be backed up with other qualities of much durability along with aesthetic appeal.

All the information one may need to ascertain and prove support in terms of the properties, application, and benefits of Stainless Steel 304 Tube may be accessed from this blog. Hence, all of them, when conducting any type of business operation, need it for proper selection and choice as far as stainless steel 304 tubes are concerned.

This grade for that matter is a member of one of the main branches under austenitic stainless steel, and as a matter of fact goes under the nomenclature name stainless steel 304. Almost contains about 18% of its chromium 8% nickel within the stainless steel’s composition, though it gets aptly named this 18/8 stainless oftentimes, being very prone as it is very prone to, because of that same nick, because of being under extreme conditions it makes the tolerance: the highest under oxidative as well as corrosive compounds.

Industrial Application: Stainless Steel 304 is used in various applications in chemical processing industries, oil and gas, power plants, etc. Other than this, it is used under corrosive conditions too. The high temperature is also one of the conditions where it might be exposed.

Food and Beverages: sanitary application suitability makes it suitable to use in the transferring of food processing industries product, breweries and also the products in the dairy farm industries with regards to if the product has the state or nature of liquid and gaseous.

Medical Equipment: The products for which it would only yield for it are such surgical equipment hospital furniture as well as the medical equipment.

Sustainability: The above product completely recycles in that, due to save its self.

In the current days, the Stainless Steel 304 Tube have become one of their favourites in any engineering and manufacturing. These properties within the stainless steel 304 tubes have become one of the strongest, effective as well as suitable materials used for various industries and several applications. As more demanding applications are targeted toward food and medicine, stainless steel 304 tubes vary in a much more aggressive environment than the different industrial environments and may perform much better while offering far greater value added to their product.

0 notes

Text

Uses of Orbital Welding in Industrial Applications

Orbital welding is a highly specialized and automated welding process used in various industries for its precision, consistency, and efficiency. It employs a mechanized system that rotates the welding arc around a stationary workpiece, typically a pipe or tube, creating seamless and uniform welds. This process was initially developed in the 1960s to meet the demanding standards of the aerospace industry, but its applications have since expanded to various industrial sectors. Below, we explore the key uses of orbital welding in industrial applications.

1. Aerospace Industry

The aerospace sector was one of the earliest adopters of orbital welding technology due to its stringent quality standards. Precision and reliability are paramount in aerospace, as welds must withstand extreme conditions, including high pressure, vibration, and temperature variations. Orbital welding is used for manufacturing critical components like hydraulic lines, fuel systems, and structural elements in spacecraft and aircraft. The process ensures defect-free joints, reducing the likelihood of failures in critical applications.

2. Pharmaceutical and Biotech Industries

Orbital welding plays a crucial role in the pharmaceutical and biotechnology industries, where cleanliness and sterility are of utmost importance. This process is used to weld stainless steel tubing for the transportation of liquids, gases, and chemicals within cleanroom environments. The automated nature of orbital welding minimizes human error and contamination, producing high-purity welds with smooth inner surfaces that prevent the buildup of bacteria or other contaminants. Compliance with strict industry standards, such as those set by the Food and Drug Administration (FDA) and the American Society of Mechanical Engineers (ASME), makes orbital welding indispensable in this sector.

3. Food and Beverage Industry

Similar to the pharmaceutical industry, the food and beverage sector relies on orbital welding for its hygienic benefits. This process is commonly used in the fabrication of stainless steel piping systems for breweries, dairies, and food processing plants. The smooth, uniform welds produced by orbital welding prevent the formation of crevices where bacteria or food particles can accumulate. This ensures compliance with health and safety regulations while maintaining product quality and safety.

4. Semiconductor Manufacturing

The semiconductor industry demands ultra-clean environments and highly precise manufacturing processes. Orbital welding is employed in the construction of gas delivery systems and vacuum systems used in semiconductor fabrication plants. These systems require leak-free and contamination-free welds to maintain the integrity of delicate processes. The precise control and repeatability of orbital welding make it an ideal choice for this high-tech industry.

5. Power Generation

Orbital welding is widely used in the power generation industry, particularly in nuclear and fossil fuel plants. In these settings, the process is employed to join pipes and tubes in heat exchangers, boilers, and condensers. These components must endure high pressure and temperature over extended periods, necessitating welds of exceptional quality and durability. In nuclear power plants, where safety and reliability are non-negotiable, orbital welding ensures adherence to rigorous standards.

6. Oil and Gas Industry

The oil and gas sector involves the transport of corrosive fluids and gases under high pressure, making reliable welding critical. Orbital welding is used to fabricate pipelines, flowlines, and subsea equipment. The process’s ability to produce consistent and defect-free welds minimizes the risk of leaks and failures, which could lead to environmental damage and financial loss. Additionally, orbital welding is valuable in offshore environments where manual welding is challenging due to space constraints and harsh conditions.

7. Automotive Industry

In the automotive industry, orbital welding is used for manufacturing exhaust systems, fuel lines, and other critical components. The process ensures strong and durable welds, contributing to the safety and efficiency of vehicles. Automation in orbital welding aligns with the industry’s push for higher productivity and consistent quality in mass production.

8. HVAC and Refrigeration Systems

Orbital welding is integral to the fabrication of pipes and tubing in heating, ventilation, air conditioning (HVAC), and refrigeration systems. These systems often operate under high pressure and require leak-proof welds to function efficiently. The precision of orbital welding helps ensure long-lasting performance and reduces the need for maintenance.

9. Marine and Shipbuilding

The marine industry uses orbital welding for constructing piping systems on ships and submarines. These systems transport fuel, water, and other fluids, often in confined spaces and under challenging conditions. Orbital welding’s ability to produce high-quality welds in tight spaces makes it a preferred choice in this sector.

10. Research and Development

Orbital welding is also prominent in research and development settings, particularly in laboratories and institutions requiring high-purity systems for chemical reactions and material testing. Its ability to produce precise and contamination-free welds supports cutting-edge research across various scientific fields.

Advantages Driving Adoption

The widespread adoption of orbital welding across industries can be attributed to its numerous advantages:

Precision: Orbital welding delivers consistent and repeatable results, reducing defects.

Efficiency: Automated processes increase productivity and reduce production time.

Hygiene: The smooth welds prevent contamination, crucial for industries like food, biotech, and pharmaceuticals.

Safety: The process reduces exposure to hazardous environments, especially in nuclear and offshore applications.

Cost Savings: Although the initial setup cost is high, the reduction in defects, maintenance, and labor costs offers long-term savings.

Conclusion

Orbital welding has become an essential tool in modern industrial applications due to its precision, reliability, and versatility. From aerospace and pharmaceuticals to oil and gas and semiconductor manufacturing, this advanced welding technique supports critical industries by meeting their unique demands. As technology continues to advance, orbital welding technology will likely find even broader applications, further solidifying its role as a cornerstone of industrial fabrication and manufacturing.

0 notes

Text

Complete processing line of paneer processing plant

Paneer is one of the most popular dairy products that are utilized in Indian cooking due to its adaptability when used in preparing both classic meals and recently trending foods. As paneer has become popular in domestic as well as international markets, there is a requirement of larger production and better manufacturing techniques. There is increasing demand for paneer that calls for automated paneer processing industries for better hygiene, uniformity, and quality production. Aviva Equipment is one of the major exporters of dairy processing technology, also offering paneer processing plant with the latest equipment of paneer processing plant to increase the rate of production and efficiency.

A common industry structure of a paneer processing plant comprises the following phases: milk reception, pasteurization, coagulation, cutting, whey separation, and packaging. Every step in the setup of the paneer production system is important to guarantee a constant quality product. The arrangement of the plant is professionally done in such a way that it facilitates large production to cater for the growing demand for paneer.

For the best results to be realized, it is important that the company has an endowed processing line enhanced by modern tools. Most of the pasteurizers, pressing systems, and packaging machines used have an advanced technology that not only makes the work easier but also hygienically handle the product. Using modern equipment it is possible to provide even texture, high quality and food safety of the finished product that is why it is difficult to imagine a efficient paneer processing plant without it.

Stages in the Paneer Processing Line

Paneer processing plant has several important steps through which it operates effectively in producing quality paneer. All the steps matter a lot for hygiene, safety, and efficiency of the organization.

Milk Reception and Storage

In a paneer processing plant the initial stage of paneer production includes receiving and keeping raw milk in a clean environment. It must be properly hand and stored in appropriate temperature to avoid spoiling and getting contaminated.

Milk Pasteurization

Paneer production begins with the pasteurization of the milk to eliminate bacterias that are hazardous to human health. This stage helps in assuring the quality and safety of the final product which makes this stage to be very vital in any processing plant of paneer.

Coagulation and Curdling

Subsequently, the milk is then coagulated through the use of some specific machines that also aid in providing a standard and uniform consistency. This step is taken to make all the curd formations similar which is required for the making of paneer.

Whey Separation and Pressing

After the completion of the coagulation process, the curd is drained off from the whey using special utensils, and the paneer is weighted to remove the extra water content. Pressing should be done properly to achieve the right level of firmness and texture as intended.

Cutting and Packaging

After the formation of the paneer, the paneer is then cut into the necessary fragile shape by the cutting machines. This is followed by packaging technology that provides a quality and hygienically packed paneer to the consumers and distributors.

Equipment Used in a Paneer Processing Plant

Milk Pasteurizers: These machines pasteurize raw milk thus using only the best and safe paneer free from any pathogenic organisms. Aviva Equipment’s pasteurizers provide temperature regulation for required outcome.

Paneer Pressing Machines: These are used for the extraction of whey and molding of the paneer where these two features are controlled to check uniformity of texture and moisture. Aviva ’s pressing machines developed for performance and effective methods of handling in hygiene.

Curd-Cutting Systems: Curd cutting is very desirable to carry out mechanically and manually using Aviva presented automated curd cutting systems make paneer production faster and do not involve much human intervention with regards to size and shape of the paneer formed.

Automated Packaging Units: Aviva’s packaging units keep the paneer hygienically packed and also quicken the process.

A well integrated and efficient paneer processing plant is thus required for achieving standardization of the final product, increased production rate and effectiveness. There is a lot to gain from the right equipment in enhancing every stage of production, from the machinery of aviva equipment in milk pasteurization and cutting and packing, so each batch of paneer is hygienically perfect and of superior quality.

Check out the wide selection of advanced equipment and technology that Aviva Equipment offer specifically for paneer production. See how Aviva Equipment can assist you in setting up your very own paneer processing plant, visit our website today to explore our product range!

https://www.avivaequipments.com/service/paneer-processing-plant/

#dairy processing equipment manufacturers in india#dairy processing equipment#aviva equipment#paneer processing plant

0 notes

Text

A Trusted Name Among the Best Dairy Equipment Manufacturers

Khambete Kothari Cans and Allied Products Pvt. Ltd., popularly known as KK Cans, has emerged as a leading name among the best dairy equipment manufacturers in India. Established in Jalgaon, Maharashtra, during the transformative years of the “Operation Flood Programme” in the 1970s, KK Cans has been instrumental in revolutionizing milk collection and dairy operations. Over the decades, the brand has set benchmarks in innovation, quality, and customer satisfaction, earning its place among the best dairy equipment suppliers globally.

A Legacy of Excellence

The journey of KK Cans began with the production of 40-litre aluminium cans, addressing the needs of cooperative milk unions in rural India. Recognizing the demand for durable and hygienic milk storage solutions, KK Cans pioneered the manufacturing of single-joint stainless steel milk cans. These innovations significantly contributed to clean milk procurement, an essential step towards improving milk quality in India.

Today, KK Cans stands tall as one of the best dairy equipment dealers, known for its dedication to quality, hygiene, and strength in every product. The company's products have become synonymous with reliability, making KK milk cans the preferred choice for farmers and milk unions across the country.

Comprehensive Dairy Solutions

KK Cans offers a wide range of dairy equipment tailored to meet the evolving needs of the dairy industry. From bulk milk coolers to turnkey solutions in milk collection, the brand continually adapts to the changing demands of private and cooperative dairy sectors. Here are some highlights of KK Cans' offerings:

Aluminium Alloy Milk Cans: A robust and economical solution, these cans are lightweight and easy to clean, making them a staple for small-scale dairy farmers.

Stainless Steel 304 Milk Cans: Known for their superior hygiene standards, these cans ensure the integrity of milk quality during storage and transportation.

Bulk Milk Coolers: Designed to maintain optimal temperatures, these coolers preserve milk freshness, reducing spoilage and ensuring quality.

Turnkey Milk Collection Solutions: KK Cans provides end-to-end solutions, including milk collection, storage, and processing equipment, catering to diverse operational scales.

Why Choose KK Cans?

As one of the best dairy equipment dealers, KK Cans’ success stems from its unwavering commitment to quality, innovation, and customer-centricity. Here are a few reasons why KK Cans remains a trusted partner for dairy farmers and organizations:

Global Presence: KK Cans’ products are not just limited to India. With exports to 42 countries, the brand has established itself as a global leader among the best dairy equipment suppliers.

Customer-Driven Innovation: Feedback from customers drives continuous improvement, ensuring that KK products meet the highest standards of quality and functionality.

Durability and Hygiene: KK milk cans and other equipment are designed for longevity and easy maintenance, promoting clean milk practices.

Affordable Solutions: By combining innovation with cost-efficiency, KK Cans ensures that its products remain accessible to dairy farmers of all scales.

Supporting India’s Dairy Revolution

The foundation of KK Cans was laid during a pivotal moment in India’s dairy history. The company’s role in the “Operation Flood Programme” underscores its contribution to making India self-sufficient in milk production. By providing high-quality dairy equipment, KK Cans has supported farmers in enhancing milk collection efficiency and quality.

This legacy continues today as KK Cans remains a leader in the industry, continually innovating to meet the modern demands of dairy operations. From rural villages to urban dairy plants, the company’s products are trusted for their performance and reliability.

Trusted Worldwide

KK Cans’ reach extends far beyond India’s borders. The brand’s global presence is a testament to its reputation as one of the best dairy equipment manufacturers. Exporting to over 42 countries, KK Cans ensures that its products adhere to international standards, making them a preferred choice worldwide.

Whether you are looking to buy dairy equipment dealers for small-scale operations or require large-scale solutions, KK Cans offers a comprehensive range of products that cater to diverse needs.

Conclusion

When it comes to finding the best dairy equipment manufacturers, KKCans is a name that stands out for its unmatched quality, innovation, and commitment to customer satisfaction. From pioneering milk can designs to offering turnkey solutions, KK Cans has been a cornerstone of India’s dairy industry and a trusted partner globally.

If you’re searching for the best dairy equipment suppliers or reliable dairy equipment dealers, look no further than KK Cans. Explore their range of products today and experience the excellence that has defined their journey for decades.

#Best Dairy Equipment Manufacturers#Dairy Equipment Dealers#Dairy Equipment Suppliers#Best Dairy Equipment Suppliers

0 notes

Text

Storage Tank Supplier in Tamil Nadu

Amma En-fab Is a leading Storage Tank Supplier in Tamil Nadu, India. Our Registered Office and Manufacturing Unit is in Ahmedabad, Gujarat, India. Amma En-Fab is a leading manufacturer and supplier of storage tanks, industrial vessels, storage silos, and other related industrial products in India. Industry Applications: Our products are widely used across multiple sectors, including Automotive Agriculture, Petroleum, Food Processing, Sugar Industry. We manufacture storage tanks using premium materials, adhering to industry standards like ASME, ASTM, and IS 2825 construction codes. The storage tanks are designed by qualified engineers and are thoroughly checked for quality at every stage of production by our quality control team. We ensure excellent finishing and on-time delivery, which is a hallmark of our service. Material Options: Carbon Steel Mild Steel Alloy Steel Stainless Steel Applications of Storage Tanks: Our storage tanks are ideal for the following industries: Oil & Gas Industry Chemical Processing Food and Beverage Factories Pharmaceutical Industry Sugar Industry Automotive Industry Marine Industry (for storing hot gases) Petrochemical Industry Dairy Plants Pesticide Industry Can I customize the size and shape of my storage tank? Yes, we offer customized storage tanks in various sizes, shapes, and capacities to meet your specific needs. Are your storage tanks safe? Yes, safety is a top priority at Amma En-Fab. Our storage tanks are equipped with safety features like pressure relief valves, emergency vents, and overfill protection to ensure safe operation. Amma En-fab is a Storage Tank Supplier in Tamil Nadu, India including locations in Chennai, Coimbatore, Madurai, Tiruchirappalli, Salem, Ambattur, Tirunelveli, Tiruppur, Avadi, Tiruvottiyur, Thoothukkudi, Nagercoil, Thanjavur, Pallavaram, Dindigul, Vellore, Tambaram, Cuddalore, Kancheepuram, Alandur, Erode, Tiruvannamalai, Kumbakonam, Rajapalayam, Kurichi, Madavaram, Pudukkottai, Hosur, Ambur, Karaikkudi, Neyveli, Nagapattinam. Contact us today for more information or to request a quote. View Product: Click Here Read the full article

#Ahmedabad#Alandur#Ambattur#Ambur#AmmaEn-fab#Avadi#Chennai#Coimbatore#Cuddalore#Dindigul#Erode#Exporter#ExporterofStorageTank#Gujarat#Hosur#India#Kancheepuram#Karaikkudi#Kumbakonam#Kurichi#Madavaram#Madurai#Manufacturer#ManufacturerofStorageTankinAhmedabad#Nagapattinam#Nagercoil#Neyveli#Pallavaram#Pudukkottai#Rajapalayam

0 notes

Text

Powered Roller Conveyors in Food Processing: Enhancing Efficiency and Hygiene

In the fast-paced world of food processing, efficiency, speed, and hygiene are key factors that determine the success of production lines. As consumer demands grow for faster delivery times and higher-quality products, food manufacturers are turning to advanced technologies to streamline operations. One such innovation that is transforming food production is the powered roller conveyor system.

These conveyors are not only enhancing efficiency but also playing a critical role in maintaining the highest hygiene standards, a vital aspect of food production. Let’s explore how powered roller conveyors are revolutionizing the food processing industry.

What are Powered Roller Conveyors?

Powered roller conveyors consist of a series of rollers mounted on a frame, with a motorized drive system that powers the rollers, enabling the movement of goods along the conveyor. The rollers are often made from durable materials such as stainless steel or food-grade plastic, ensuring longevity and resistance to wear and tear. This system can be customized to accommodate different product types, sizes, and weights, making it suitable for various stages in food processing, from raw material handling to finished product packaging.

1. Boosting Operational Efficiency

One of the key advantages of powered roller conveyors in food processing is the improvement in operational efficiency. These systems are designed to automatically transport products from one station to another, eliminating the need for manual labor. This reduces human error, minimizes delays, and ensures that the production line operates smoothly.

In food processing facilities, powered roller conveyors are especially useful for handling bulk products such as fruits, vegetables, packaged items, or meat products. Since these conveyors can be integrated with automated sorting, weighing, and packing systems, they significantly reduce downtime and improve throughput. Whether it's moving raw ingredients or finished products, these conveyors keep everything moving with minimal disruption, leading to faster production times and increased overall output.

2. Hygiene and Food Safety: A Priority

Food safety is a top priority for any food manufacturer. Powered roller conveyors are designed with hygiene in mind. They are often made from stainless steel or other non-corrosive, easy-to-clean materials that prevent the accumulation of contaminants. Since these conveyors are integral to the transportation of food items, maintaining cleanliness is critical to avoid contamination.

The design of powered roller conveyors makes it easier to clean between production runs. Unlike traditional conveyor systems, which may trap food particles in hard-to-reach places, powered roller conveyors have a streamlined construction with fewer joints, seams, and crevices, reducing the risk of bacterial build-up. Moreover, many systems are equipped with smooth, non-porous surfaces that resist the accumulation of dirt and grime, which is especially important in food handling.

3. Temperature Control and Compliance

Certain food products require precise temperature control during processing. Powered roller conveyors can be customized to include features that regulate the temperature of the rollers, ensuring that products are kept at optimal temperatures throughout the production line. For example, refrigerated powered roller conveyors are often used in the handling of perishable food products, like dairy, meats, and frozen foods, to prevent spoilage during transportation.

Moreover, powered roller conveyors can be integrated with sensors that monitor temperature, humidity, and other variables, ensuring that food safety regulations are adhered to. This is essential for compliance with standards set by food safety organizations such as the FDA, USDA, and European Food Safety Authority (EFSA).

4. Space Optimization and Customization

In food processing plants, space is often limited, and maximizing available floor space is crucial. Powered roller conveyors can be customized to fit specific layouts, optimizing production areas and reducing bottlenecks. These conveyors are also modular, allowing for easy expansion or reconfiguration as production demands change.

By utilizing powered roller conveyors, food processing facilities can maintain efficient workflows even in compact spaces, ensuring smooth transitions from one stage of production to another without sacrificing valuable real estate.

5. Improved Worker Safety and Ergonomics

Another significant advantage of powered roller conveyors is their positive impact on worker safety. In food processing environments, where heavy lifting and repetitive motions are common, powered roller conveyors minimize the risk of workplace injuries. Workers no longer need to manually lift or carry heavy items from one station to the next, reducing the chances of strains, sprains, or other musculoskeletal injuries.

Additionally, by reducing the need for manual intervention, powered roller conveyors lower the chances of accidents caused by human error. The conveyor system’s automated nature allows workers to focus on other critical tasks, ensuring that the production line operates smoothly and safely.

6. Cost Efficiency in the Long Run

Although powered roller conveyors may require a higher initial investment than manual systems, their long-term benefits outweigh the upfront costs. The automation of the food production process helps reduce labor costs, while the system’s durability ensures minimal maintenance and repair expenses. Furthermore, the ability to streamline operations leads to increased production volumes and improved profitability over time.

Conclusion

Powered roller conveyors are transforming the food processing industry by enhancing operational efficiency, ensuring high levels of hygiene, and promoting worker safety. Their ability to handle large volumes of food products, while maintaining compliance with strict food safety regulations, makes them indispensable in modern production facilities. As the food industry continues to evolve, these conveyor systems will undoubtedly play a crucial role in driving innovation, quality, and efficiency, helping food manufacturers meet the growing demands of a competitive marketplace.

By adopting powered roller conveyors, food processing plants can stay ahead of the curve, ensuring that they deliver high-quality products to consumers while maintaining a safe, efficient, and hygienic environment.

0 notes